Non-destructive testing of rails

TVEMA produces rail flaw detection systems capable of testing the speed and high-speed railway sections in the speed range from 0 to 140 km/h.

Purpose

Flaw detection systems are designed to record flaws in rails by various NDT methods in the speed range from 0 to 140 km/h without reducing the reliability of testing.

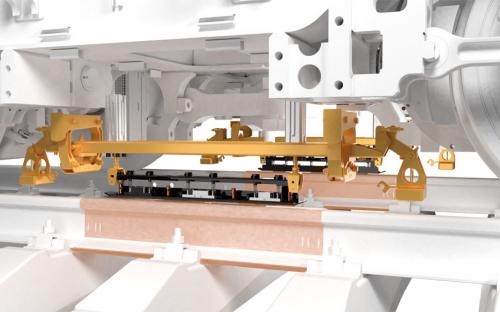

Basis of these systems is the principle of modularity simplifying the installation of equipment on a rolling unit and replacing its components in the process of their modernization.

Innovative design of the underfloor equipment makes it possible to place it both on a specialized flaw detection bogie and on a standard car bogie of most types of cars, between wheel sets. The latter arrangement makes it possible to exclude a specialized bogie from the composition of flaw detection equipment.

The software implements the presentation of control data in accordance with the requirements applicable to any railways in the world. All received information is processed in real time, recorded and saved for further analysis and planning of works on the routine maintenance and repair of the track.

Ultrasonic Flaw Detection

The increase in the movement speeds and the number of pairs of trains contribute to an increase in the factor of track occupancy, which forces to increase the speed of ultrasonic inspection. This entails a decrease in the stability of acoustic contact, and therefore, reduces the reliability of testing. Our system makes it possible to avoid this. It provides accurate positioning of the search systems relative to the rail top due to the interaction of the magnetic fields of the permanent magnets included into its composition with the field of the magnetized rail. The system uses transducers that emit ultrasonic waves with certain angles of rotation to the working and inworking surfaces of the rail head, which leads to the absence of "deaf" areas.

Advantages

- Operating speed up to 140 km/h.

- Low cost.

- Searching sliding systems ensure stable operation even in the harshest climatic conditions.

- Simplicity of the design makes it extremely easy to install and dismantle the acoustic unit itself and the whole system.

- Slight running time of ultrasonic waves in the acoustic unit protector, which provides a significant reliability and area of testing.

- Design of the acoustic unit and the wide assortment of converters produced by TVEMA make it possible to implement any scanning pattern that meets the requirements for detecting flaws according to regulatory documents of various countries.

- Unlimited passage of turnouts of any projects.

- The use of water as a contact liquid and its direct supply to the acoustic units through the fittings, which ensures its minimal losses and the environmental sustainability.

Scope of application

Network of railways and subways of the Russian Federation and foreign countries.